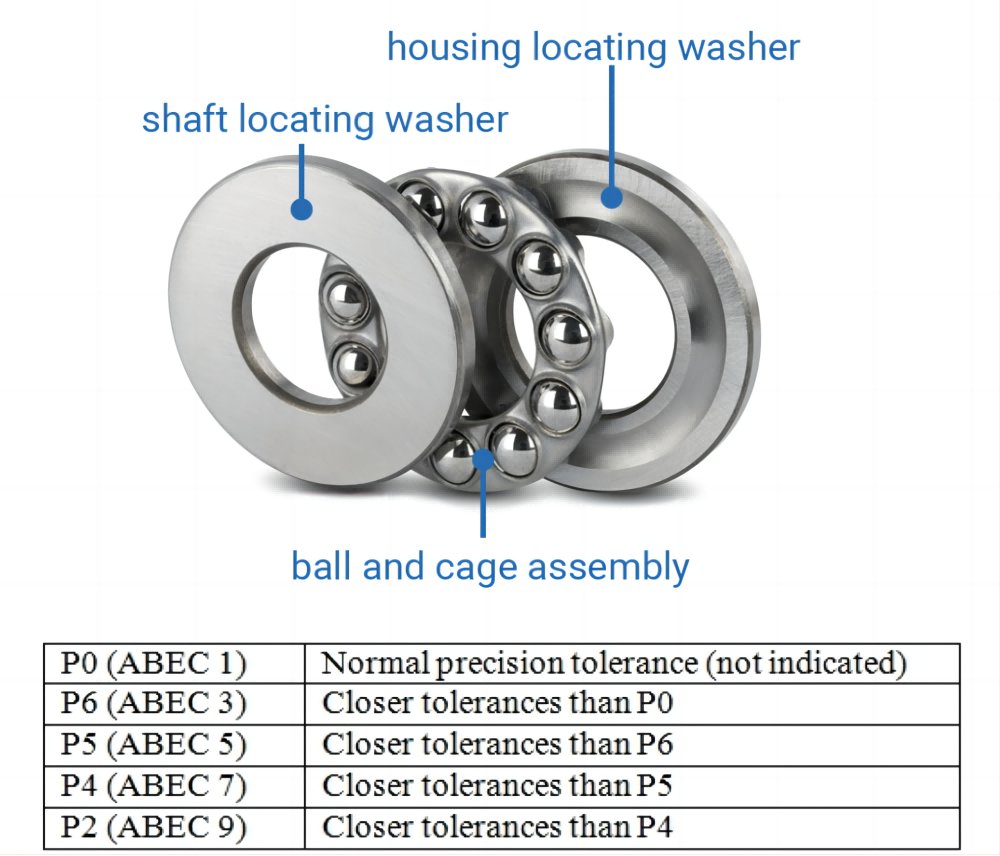

Thrust ball bearings are designed to manage thrust (axial) loads and provide high performance in a small envelope. They are composed of a shaft washer, a housing washer, and ball and cage assemblies. These bearings can accommodate axial loads in one direction and must not be subjected to any radial load.

They are commonly found in automotive applications, marine propulsion systems, material handling equipment, compressors, and in various other industrial equipment where high axial loads need to be supported. Due to their design, they facilitate low friction,smooth running, and low noise.

Single-Direction Thrust Ball Bearings

Single-direction thrust ball bearings are comprised of two bearing washers (a shaft washer and a housing washer) and a single cage containing the balls. They can sustain axial loads in one direction.

Features

* Specialized design

A cage contains the balls while the grooved aligning seat washer guides them.

* Dedicated components

Washers attached to the shaft are called “shaft washers” and those attached to the housing are called “housing washers” (fixed

rings).

* Support axial loads

Single-direction thrust ball bearings can take axial loads in one direction.

Applications

Printer peripheral equipment, ball screw support sections of precision positioning stages, automatic guided vehicles (AGVs),radial drilling machines, fishing reels

Double-Direction Thrust Ball Bear

Double-direction thrust ball bearings use three washers, with two cages containing the balls. This shaft washer is sandwiched between the two cages, allowing the bearing to take axial loads in both directions.

Features

* Specialized design

A cage contains the balls while the grooved aligning seat washer guides them.

* Dedicated components

Washers attached to the shaft are called “shaft washer” and those attached to the housing are called “housing washers”.

* Support axial loads in both directions

True to their name, double-direction thrust ball bearings can sustain axial loads in both directions. Thrust ball bearings with aligning seat washers help reduce the effects of mounting errors.

Applications

Vacuum pumps, disc hubs in agricultural machinery, compressors, press machines, clutch breakers

Item Code | Dimensions(mm) | Weight(g) | dynamic load(N) | Static load (N) | ||

d | D | B | ||||

51405 | 25 | 60 | 24 | 334 | 56000 | 89500 |

51406 | 30 | 70 | 28 | 519 | 73000 | 126000 |

51407 | 35 | 80 | 32 | 769 | 87500 | 155000 |

51408 | 40 | 90 | 36 | 1100 | 103000 | 188000 |

51409 | 45 | 100 | 39 | 1460 | 128000 | 246000 |

51410 | 50 | 110 | 43 | 1940 | 147000 | 288000 |

51411 | 55 | 120 | 48 | 2580 | 181000 | 350000 |

51412 | 60 | 130 | 51 | 3160 | 202000 | 395000 |

51413 | 65 | 140 | 56 | 4100 | 234000 | 495000 |

51414 | 70 | 150 | 60 | 5050 | 252000 | 555000 |

51415 | 75 | 160 | 65 | 6150 | 254000 | 560000 |

51416 | 80 | 170 | 68 | 7210 | 272000 | 620000 |